Would you look at that? It’s well over 2 years since I did my first serious modding to the Ender 5 plus. A lot happened since then. I had quite some construction work to the house and had to store my printers elsewhere, then became father again. Safe to say, I had other priorities. Those priorities haven’t changed that much, but I am getting more time to do some printing… and modding.

I have a few reasons to start modding again. And the first one is pretty simple… I like tinkering. Then again, I don’t intend to fix things that aren’t broken, and the printer isn’t broken, per se. But there are some annoying factors that came into play.

- My new office setup requires my FDM printers to stand on top of eachother. The Ender 5 plus is being fed from the back and getting there is quite a hassle.

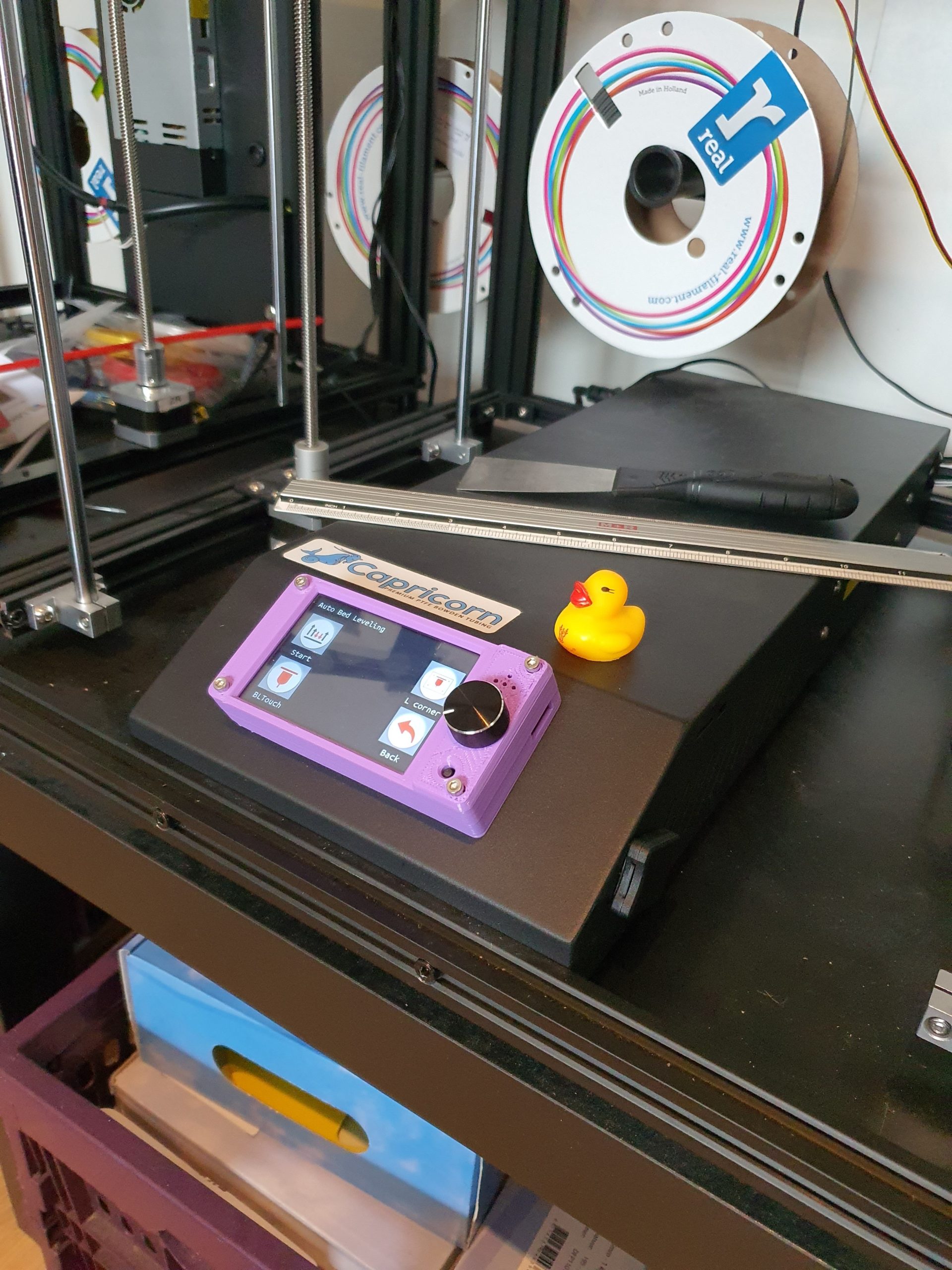

- The Ender 5 plus extruder is, besides an upgrade to all metal hotend and capricorn tubing, basically stock. I don’t particularly have a problem with it, but I believe the bowden setup is giving me some issues and I want to try out direct drive.

- I don’t like all the dust in the v-slots of the rails, so I want to cover that up.

- I have to do a lot with sd-cards in my printing process and some have already failed. I wanted to try (my initial plan when I started 3D-printing) printing from a Raspberry Pi running OctoPi. Back then, it would basically just upload the gcode file and start it on the printer. But seeing all the posts about Klipper, I wanted to try that out as well. Because of Raspberry Pi’s are still low on stock and the ones I have are too slow, I decided to use an Odroid XU4 running Debian. (Odroid image)

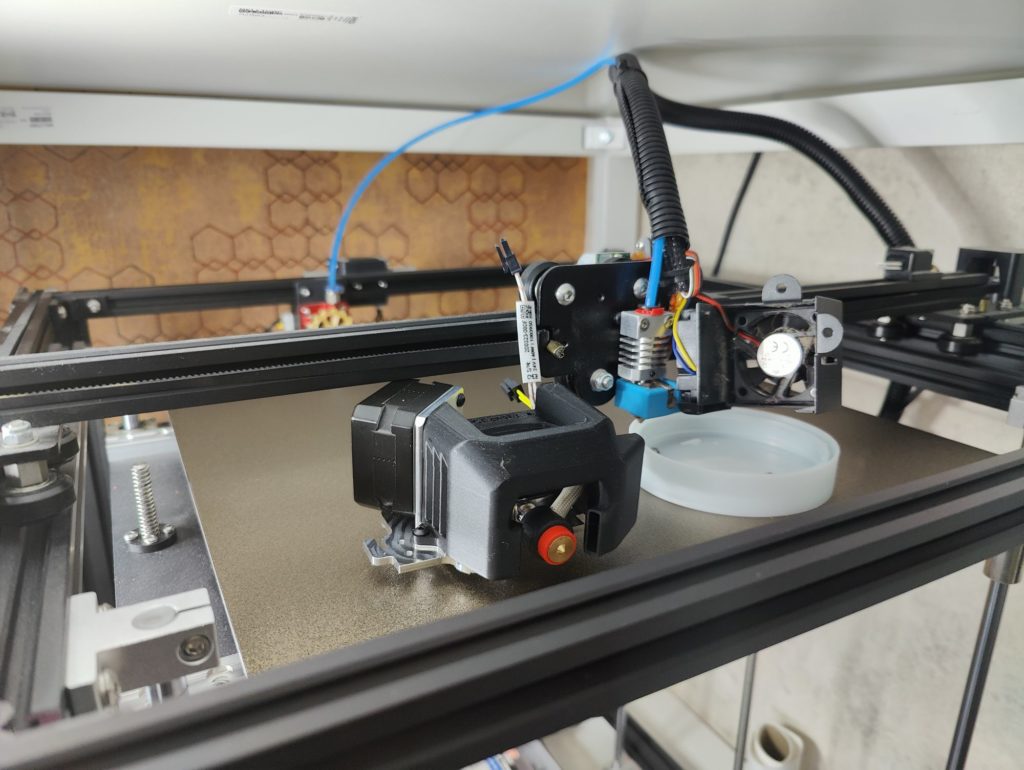

So after some research, I found myself deciding between the regular Micro Swiss NG and the REVO version. Both have good reviews and are well used. Again, I don’t plan to do a lot of nozzle changes at the moment, but the REVO setup is really nice to do so. I’ve had problems with nozzle swaps before, but on the other hand, those brass nozzles come cheap by the dozens and the REVO nozzles are a bit of an investment. I decided on the REVO anyway, because I feel that’s the more future proof setup.

Because I don’t want to make too much changes at the same time, I will upgrade the extruder first and maintain my Marlin setup, then print at least a 3DBenchy to verify all axis are working before continuing.

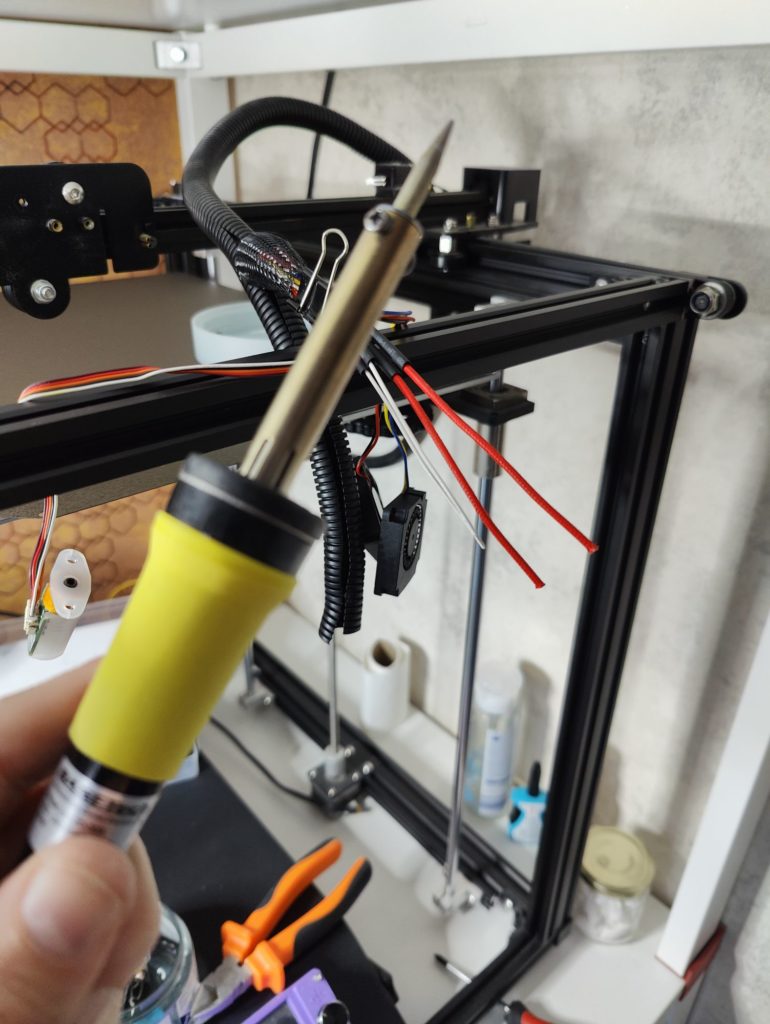

For installing the extruder, I could really follow Micro Swiss’ instructions quite well. One thing I did not do was using the butsplices to join the cables. Because I want everything to be a lean as possible, I soldered the wires together.

So I got out my trusty and somewhat dusty soldering iron and whenever the instruction said to splice the wires, I soldered instead.

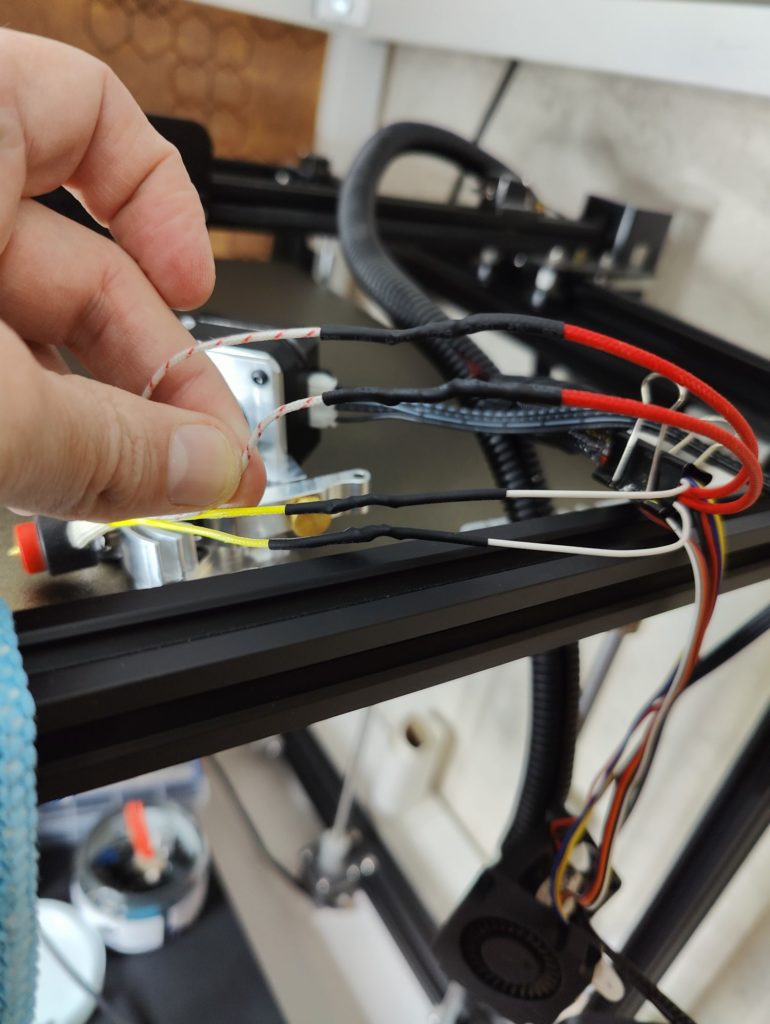

Before connecting the wires, I added a shrinking tube so I could seal the wires propperly.

The end result is a nicely joined wire without anything exposed.

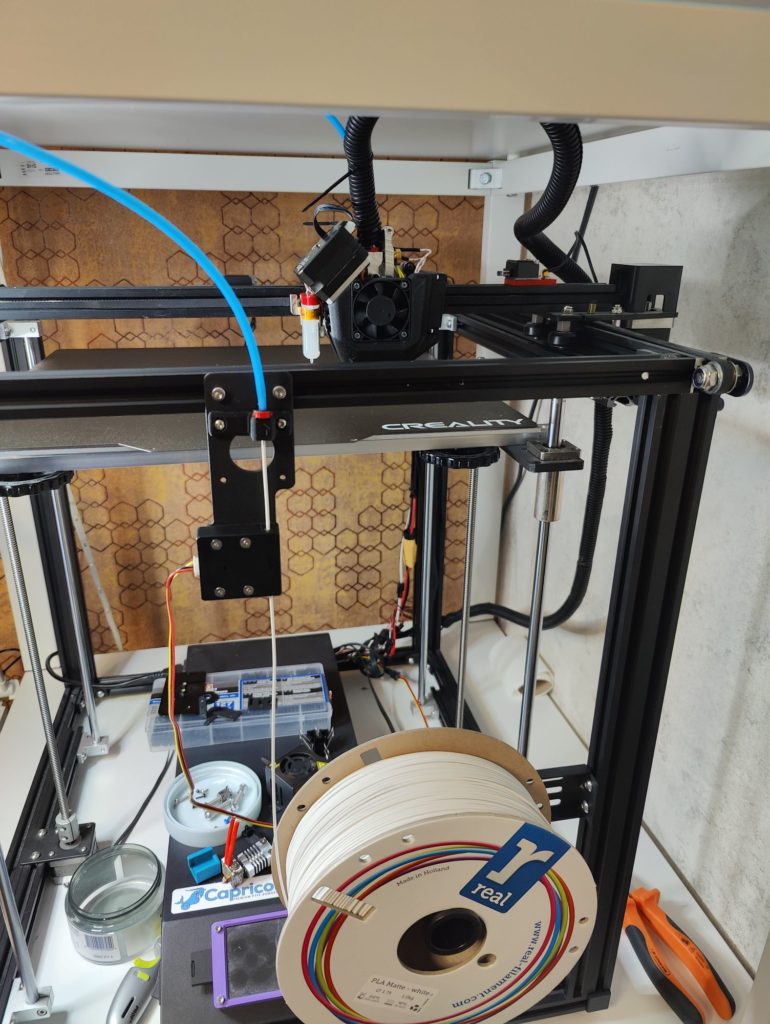

Then I could get everything back together and seal the wire harness with zipties.

I also moved the fillament detection sensor, ptfe tubing and spoolholder to the front now.

Then, I updated the e-steps on Marlin with Micro Swiss’ gcode file as instructed.

Finally, I sliced and printed a 3D Benchy to see if everthing was setup correctly.

Final result: working printer with marlin.

Next up: Upgrading to Klipper!

0 Comments