One thing has to be said about Creality3D’s Ender 5 plus… She aint quiet. I love the printer though, it’s a fresh breath compared to the M3D Quad. I am actually able to finish prints and they look and feel good.

But, for some weird reason (*cough*money*cough) Creality decided to put in the old spec PCB instead of the silent version like they did with the Ender 3 Pro. The old spec had load stepper drivers and it makes the machine have a high pitched squeek. I can hear it one floor below when I’m sleeping and it makes sure I don’t get my rest.

Obviously, I already read about this beforehand, but I wanted to see hear the sounds itself. Let’s just say it took about a week before I decided I wanted the silent board. Then it took a bit just to find a store that had it in stock. With the COVID-19 run on 3D printers to print masks and such, this board was nowhere to be found. This weekend I found some in stock at my local 3d printer supplier (123-3d.nl) so I ordered on.

Installation

I used this guide to help me installing. I have watched a great deal of his videos and I can highly recommend it. I like how he explains the why behind a change and how he verifies every change. I must admit, I don’t do my verifications quite as thorough as him, but I agree with his ground rule: only do 1 change at a time and verify that change. I verified mine with a bed level test on thingiverse. This is a fairly simple test of 2 squares, but it was enough for me to compare the results of the two PCB’s.

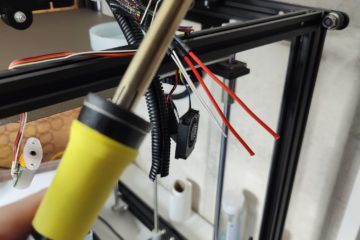

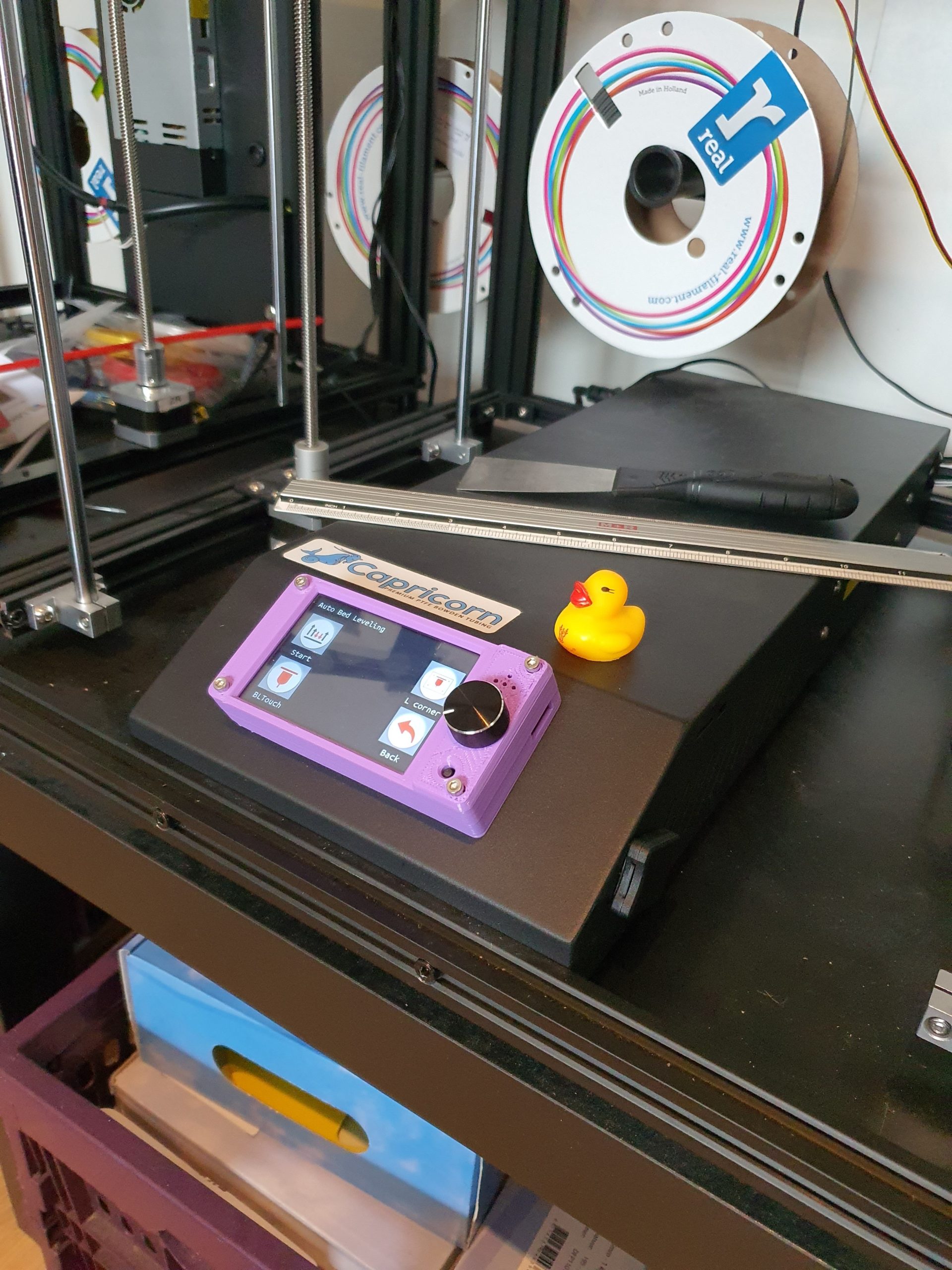

The installation went quite smooth, although on the original PCB they decided to glue every connector with a big hump of glue. If that weren’t present, the switch would be about 15-30 minutes of work. Now it took me over an hour. But still, quite easy: unscrew the entire original board, then screw down the new. Then, one by one, switch the wires to their respective slot on the new board. (layout is exactly the same)

Why not a 32-bit / SKR board?

I have asked this question myself as well. The answer was pretty simple. The problem I was fixing was the sound. I have no problems (yet) with an 8 bit board. Ofcourse I will switch to 32 bit sometime in the future, but for now I don’t think I need it just yet. Secondly, I wanted an easy upgrade with immediate results. Switching to SKR or Duet as some suggested, would perhaps be best in terms of end result, but to get there I would require upgrading my soldering skills, rewiring, etc.

Results

Night and day. As I read before, but didn’t knew a stepper driver could have this effect. I thought the Ender 5 Plus’ sound came from the motors itself, but apearantly the drivers do a lot to it. I still need to read up on the theory, but the difference is insane. Now I can actually leave a print on while in a conference call with work, even with the machine being on the same desk! I even had to look at it from time to time because it sounded like it was running idle.

When everything was level and checked, I started a full print.

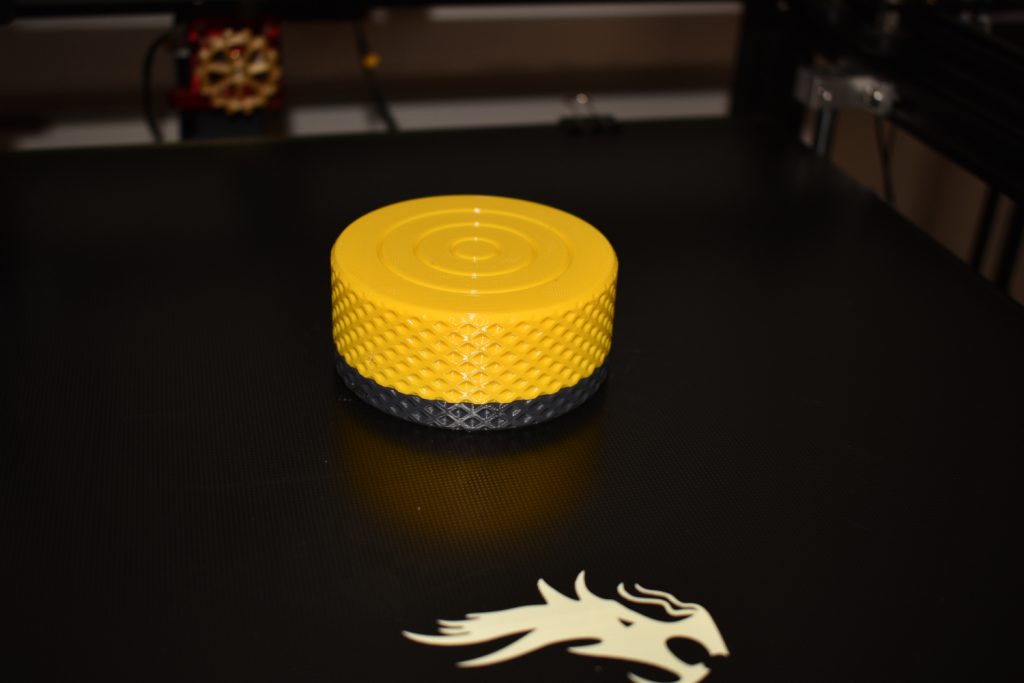

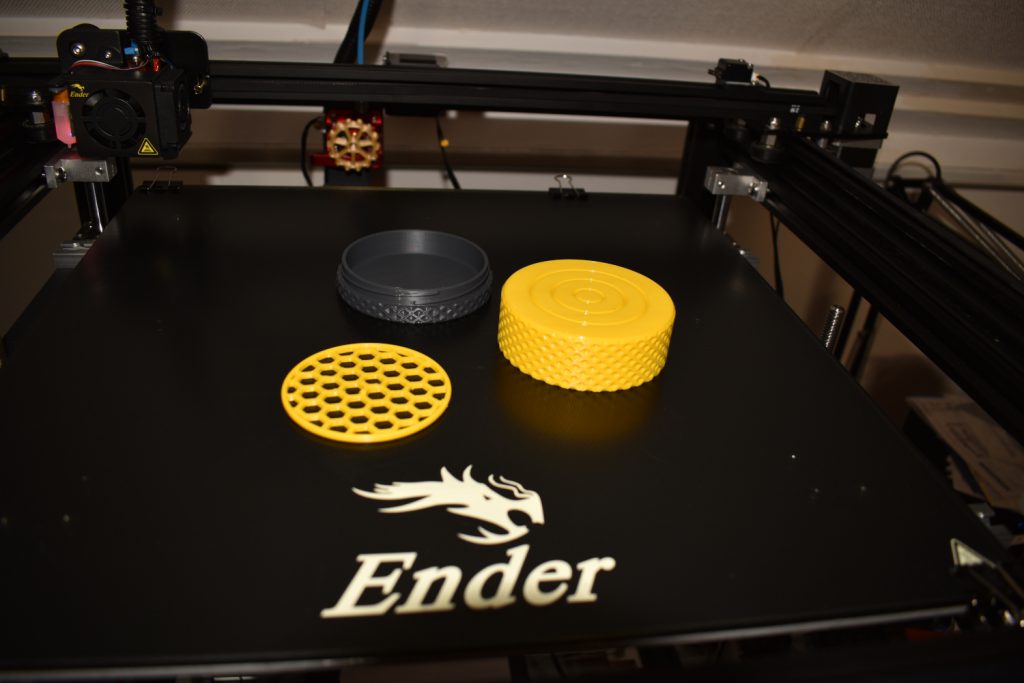

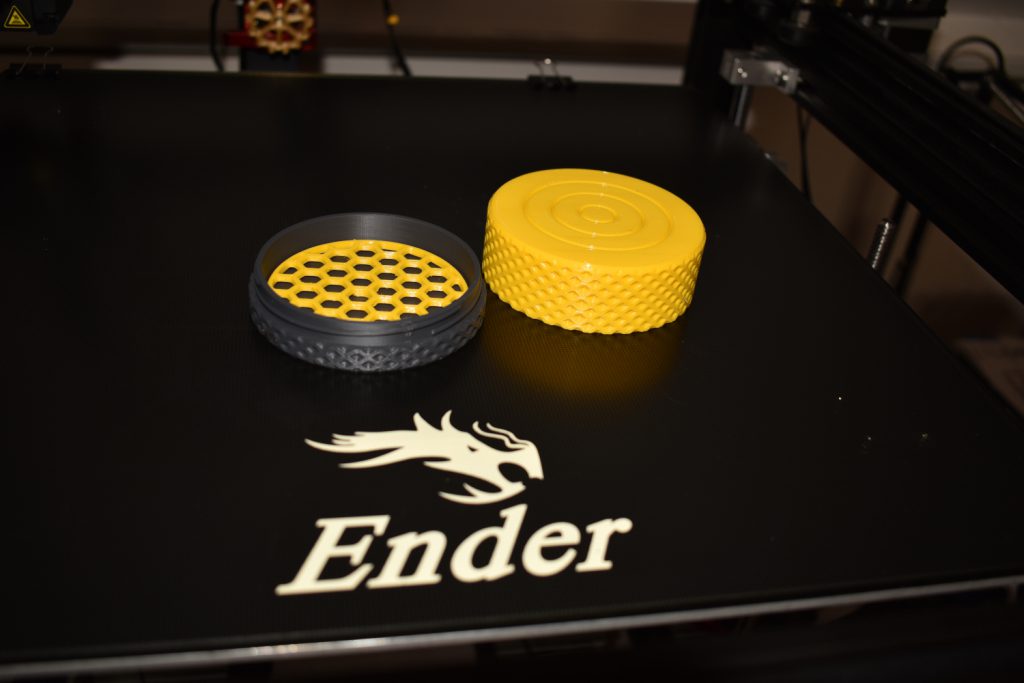

It’s a 3 part print, with a base (grey) a lid and a tray to make sure the wet soap won’t stay stuck on the bottom. I am absolutely stunned on how well this print came out. I’m not sure if this is just the regular way a print should come out, but I never got anything close to this quality on the Quad. Maybe, when I have more experience with this machine, the Quad will reveal it’s secrets to me too… #lifegoals

This is a soap box, designed for the round Lush soap bars. My wife loves those bars and hates the tin lush sells for it.

So when I complained about not having a fun thing to print, she sent me the link to this thingiverse model.

0 Comments