As I mentioned before, the M3D Crane owners group on facebook is filled with minds far brighter then mine. Obviously, being a 3d printing group, it’s filled with heavy modders. From that, the Quaden setup came, but also constructions with top fans, better fan shrouds and basicly everything you can imagine that M3D could have thought about….

I was still getting more problems with clogs and getting the quaden dialed in proved hard as well, so I decided to create the Wire Hardness Top Mounted Fan mod. I actually had a decent print on it, but then found another issue with the concept: wiring. I’m no electrical engineer, but I know bits and pieces. I don’t mind to solder (though I don’t do it very often) but I then have to solder it into a specific molex connector. I couldn’t find that in the netherlands, I’d have to ship it from the States, with some horrible shipping rates. Fun fact: In order to get free shipping, I had to buy about 500 connectors and it would have been cheaper then buying 50.

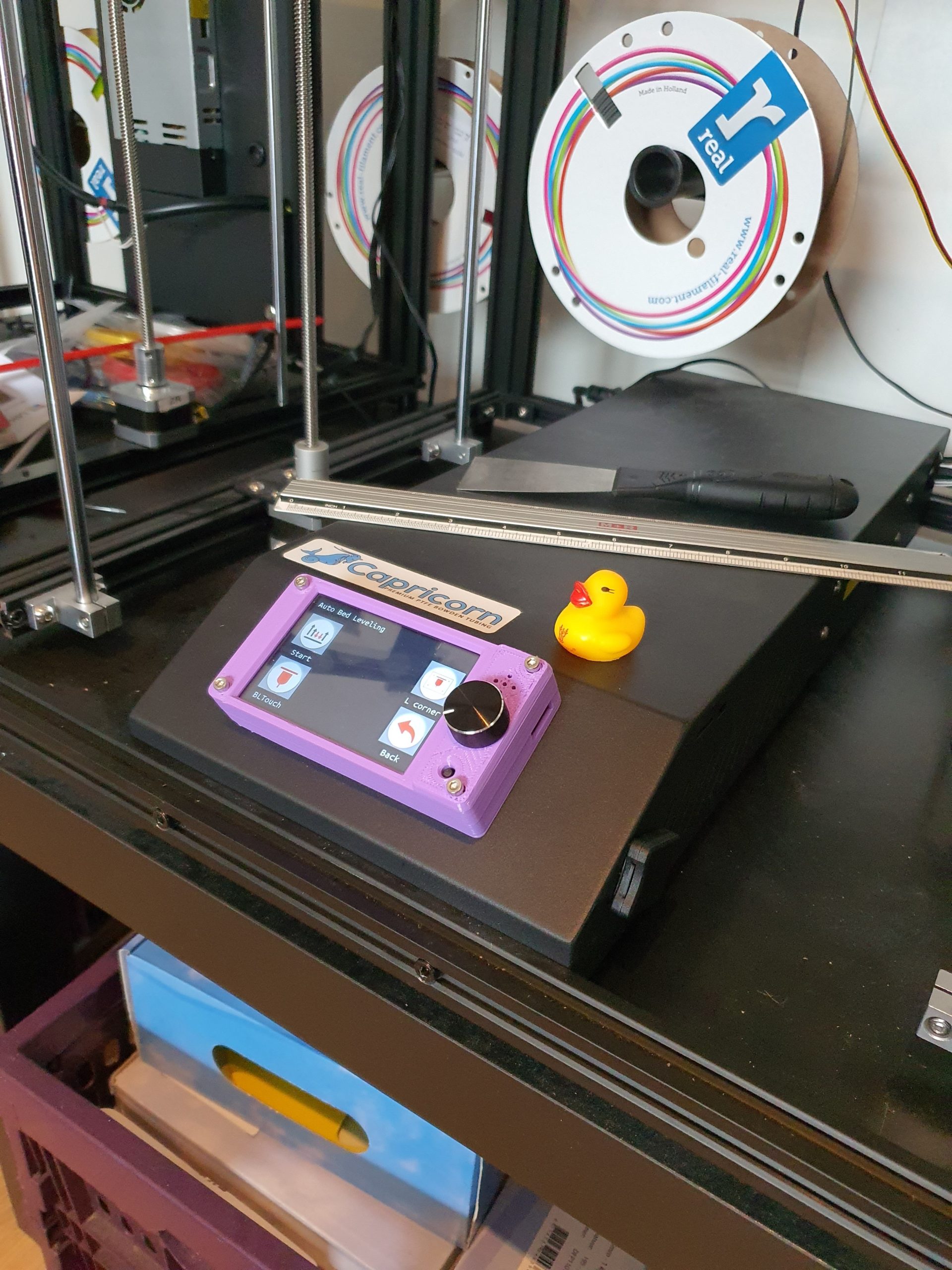

So I decided I’d go to the community store page, offered by Joshua R. Taylor via his website jrt3d.com and get the top fan kit. Usually, shipping from the States takes about a week. But now with COVID-19 all around the globe, less planes are flying so I had to wait for almost 3 weeks. But this week it finally arived! First all, I told Joshua this personally already, but his packaging is perfect. I remember my printer coming in which was shipped in a box with barely anything to protect it from harm. Just a bit of bubblewrap and it was sliding and bouncing in the box. Joshua, on the other hand, bubblewraps each part, clearly labels all bags of screws and then protects that with brown paper. Nothing could move or shift and I think even Ace Ventura would have a hard time breaking it. 🙂

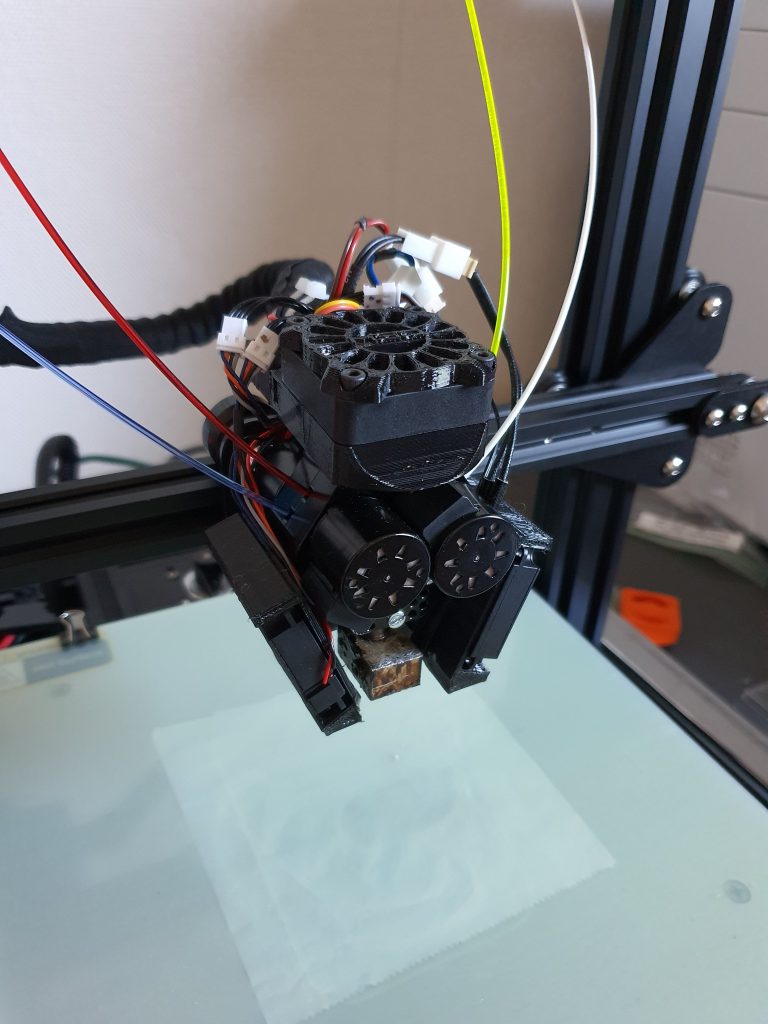

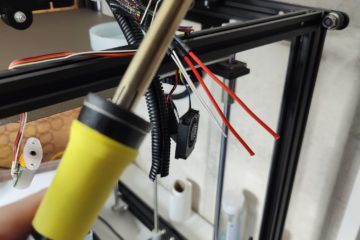

I’m now more or less back to the stock crane. The community figured out some problems and most of it is cause by heating of the motors. One way of mitigating this problem is by removing the motors from the head, like I did with the Quaden setup. The other is adding more cooling to the motors as I have right now.

I am still learning a lot about printing and about printing with this device. I was warned beforehand: this is a horrible machine to start with, but once you know and tamed the beast, it can be great. I thought I tamed it on multiple times. I thought I had it all under control, but if you slack just once stuff like this happens.

I set it all up and waited for the first layer to go on. This, my current hypothesis, the nozzle wasn’t held properly (I didn’t check it well enough) and with the pressure buildup from 4 motors the entire nozzle just blew out violently. I was in another room so didn’t see or hear it happening, but the PTFE was knocked out, my glass fiber plate was vaulted. To be frank, it could have been much worse…

So I went back to the owners group, analysed the problem and it was indeed most likely the nozzle not being held propperly. One possible reason might be that I’m not using the original screw anymore. I had my first one break and force me to replace part of the head. Not a real issue, ofcourse, except I have to fly everything in from the States as there is no reseller in Europe. Therefor, I also have customs to pay, so in all this is an expensive machine. So after getting that part replaced I also got a new TX10 screw. In that time after I did a lot of disassembly and assembly of the head, for minor issues, for gaining knowledge on the inner workings of it all. The screw delivered is really tight and in hind-sight I didn’t have to unscrew it entirely everytime. Long story short, the screw head is shredded and I had to use an electric drill to get it out carefully not to break another one. So then I grabbed a screw from my box thats the same size. So I guess that decision came back to bite me in the rear and it’s something I have to keep in mind to recheck every time I replace a nozzle. Also, I decided not to swap nozzles unless this one dies.

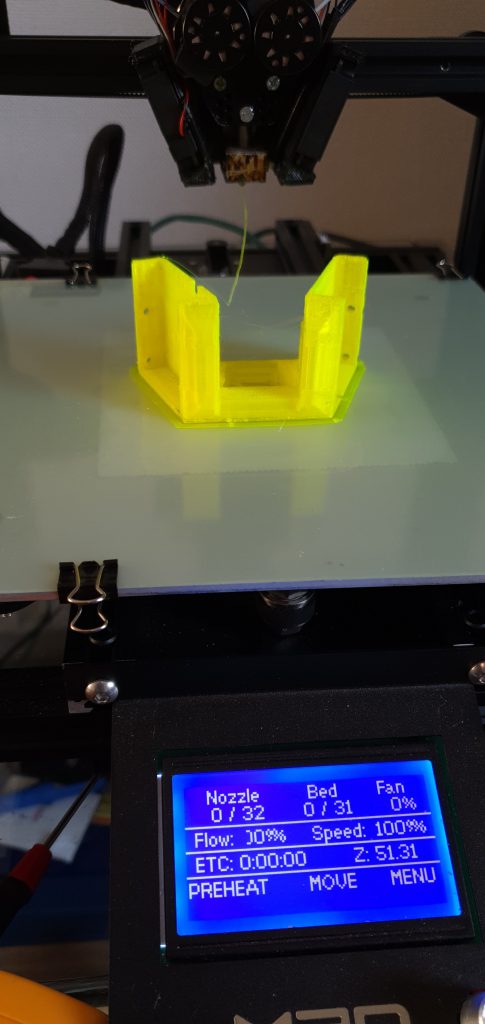

And with all this, I almost ruined the new fan shroud I had installed, so first print when setting up is a new fan shroud, just to have it on shelf … I will be printing a few of these, just to be sure 🙂

Also I switched to PETG entirely. This devices likes it hot and was actually designed with PETG in mind. So I bought some more PETG spools and the results are indeed better already. Perhaps I will get a single extruder machine for big single color PLA prints in the future if a good printer comes along.

0 Comments